By using special discharging bars suitable for high web speeds, the transport problem in the shingle can be solved.

Electrostatic discharge of printed products in front of the shingle

Transport of printed products in the shingle

Printed sheets always have a larger volume at the waistband than at the open side due to the fold. In order to deliver a stable package of printed sheets from the presses, the sheets must be interleaved crosswise. The sheets run in a shingled manner or individually into the receiving shaft of the compensating stacker. Depending on the thickness of the printed product, a certain number of sheets are piled one on top of the other, then the pile is rotated by 180°.

Can there be transport problems in the shingle?

In front of the compensating stacker in the shingled stream, two copies repeatedly adhere to each other, especially with lightweight papers. This leads to transport problems in the shingled stream, especially with 90° curves.

Our solution

Which Eltex components are used?

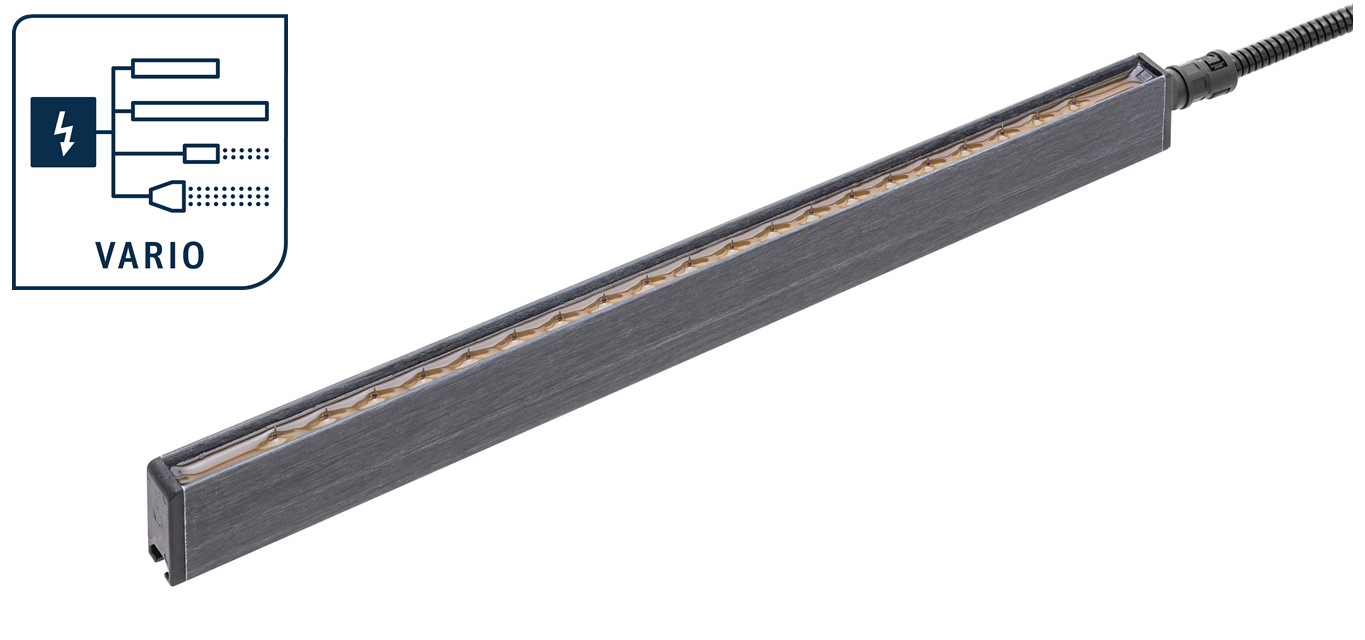

blueBAR R50

The robust all-rounder bar The VARIO discharge bar blueBAR R50 creates a significantly higher active discharge capacity than most discharge techniques. The isolated ground conductor enhances the E-field at the active tips, contributing to increased production and velocity of charge carriers. Thus, significantly more positive ions and free negative electrons are available than with conventional bars. At the same time, the bars have a high passive discharge capacity. The resistance-decoupled tips ensure good discharge performance and make the bar absolutely short-circuit and touch-proof.

PRO IONIZER ES61

The PRO IONIZER is a powerful and flexible device which is suitable for absolutely any application. With the new Performance Control, each discharging component can be supervised and displayed separately. With different adjustable process parameters and several interfaces the PRO IONIZER sets a new benchmark. Click here for more information! Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information on fieldbus integration