Suitable discharge bars with additional air duct are mounted in the best possible position in the drop chute.

For the detailed solution description of this application or a consultation on your application problem, click here:

Suction pipes are used, for example, to transport punching or cutting waste from a printing press via a pipe system to a waste disposal facility. The same applies to edge trim suction in plastic film production. The material waste is compressed in the stationary compactor and then transported to the transport container. The full container is transported away by truck.

Electrostatic charging of the substrates occurs in the production machines and in the pipe system due to contact and separation. The charged material sticks to the side walls of the chute and clogs the system. The material also covers sensors that check the fill level of the system. The system malfunctions, which can cause the machine to stop.

Suitable discharge bars with additional air duct are mounted in the best possible position in the drop chute.

For the detailed solution description of this application or a consultation on your application problem, click here:

The following Eltex products have been installed and tested on site by our experts. If you would like to learn more or have any questions, please do not hesitate to contact us.

The PRO IONIZER is a powerful and flexible device which is suitable for absolutely any application. With the new Performance Control, each discharging component can be supervised and displayed separately. With different adjustable process parameters and several interfaces the PRO IONIZER sets a new benchmark. Click here for more information! Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information on fieldbus integration

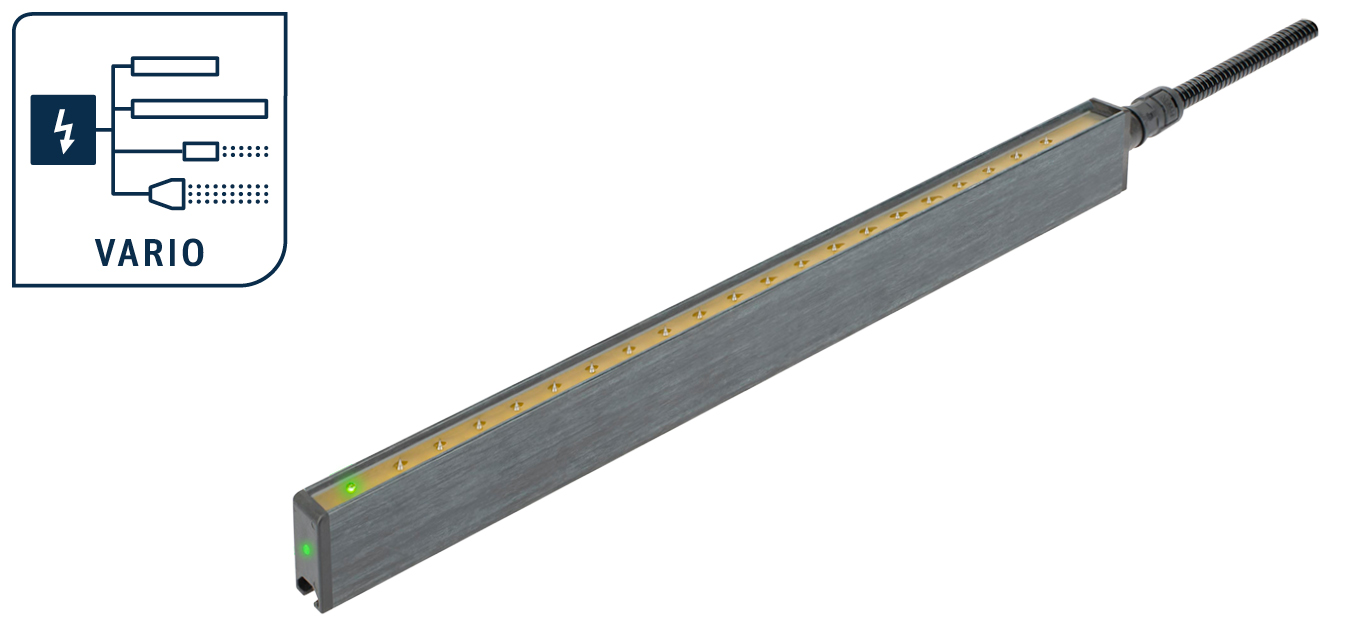

The robust all-rounder bar The VARIO discharge bar blueBAR R50 creates a significantly higher active discharge capacity than most discharge techniques. The isolated ground conductor enhances the E-field at the active tips, contributing to increased production and velocity of charge carriers. Thus, significantly more positive ions and free negative electrons are available than with conventional bars. At the same time, the bars have a high passive discharge capacity. The resistance-decoupled tips ensure good discharge performance and make the bar absolutely short-circuit and touch-proof.

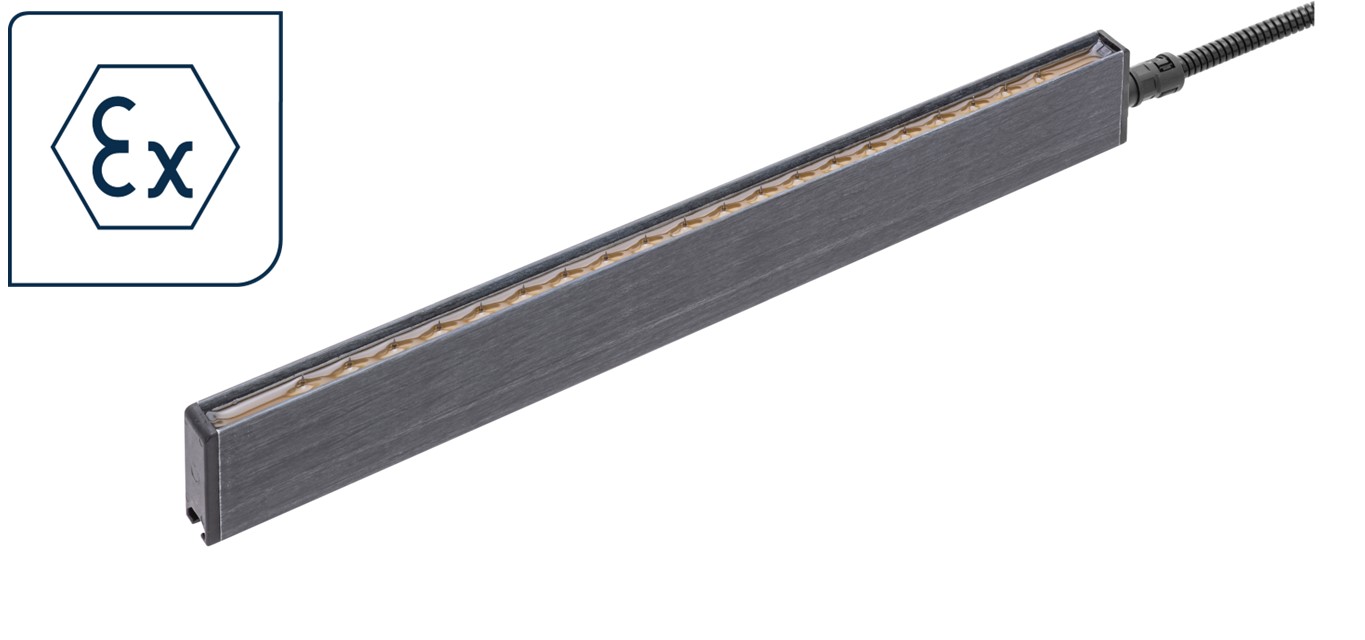

Safe discharge also in the EX area The VARIO high-voltage power supply IONIZER ES53 and the associated Ex discharge bars are available for active discharge of electrostatic interference in hazardous areas. The IONIZER ES53 complies with the requirements of the Ex approval of the associated discharge bars (details in the operating instructions for the bars).

Safely discharged even in EX areas The exBAR EXR5C is operated with an AC voltage of 5 kV at 50...60 Hz and is approved for use in Group IIG and IID potentially explosive atmospheres. Corresponds to equipment category 2 (zone 1 operating equipment).