Electrostatic flashovers on personnel are significantly reduced by using the highly effective flexION R60L discharge bars.

Electrostatic discharge of car seats

Car seats are covered with the seat cover.

The car seats arrive to the assembly station wrapped in a foil and are unpacked there. During the assembly of the car seats, the foam is covered with integrated and insulated steel linkage, with the textile cover. This work is done manually.

Can electrostatic discharges occur on personnel during assembly?

When the foam is unpacked from a protective film, handled and moved on an assembly table, etc., the foam seat becomes electrostatically charged and affects the charge on an insulated metal linkage. If the linkage is touched accidentally, sparks are discharged onto the employees, even through protective gloves.

Our solution

Which Eltex components are used?

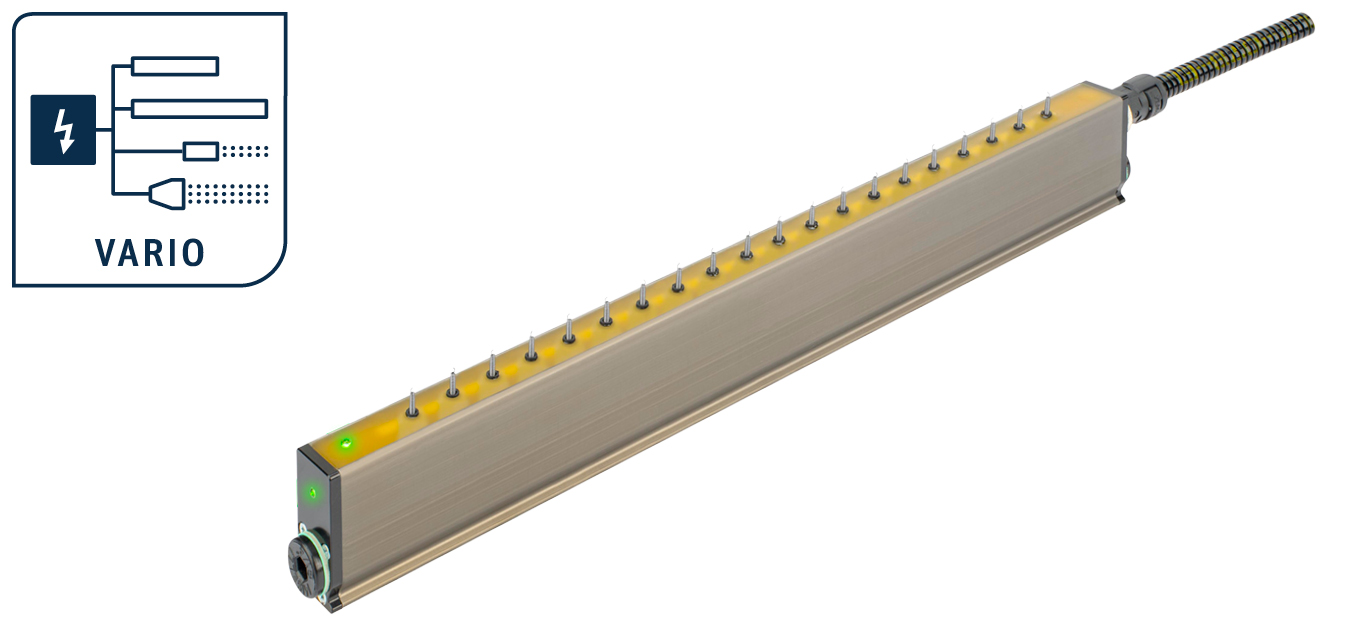

flexBAR R60L

HIGH-END discharge for highest discharge performance The VARIO discharging bar flexBAR R60L with its free-standing, air-assisted spring tips has a very high passive discharge effect, which enables active operation even at low AC high voltage. To increase the range, a small amount of air optionally flows through the hollow spring tip. The air flow additionally serves the continuous cleaning of the emission tip.

PRO IONIZER ES61

The PRO IONIZER is a powerful and flexible device which is suitable for absolutely any application. With the new Performance Control, each discharging component can be supervised and displayed separately. With different adjustable process parameters and several interfaces the PRO IONIZER sets a new benchmark. Click here for more information! Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information on fieldbus integration