Highly effective discharging bars must be used for highly charged printed sheets. These must also be usable in unfavorable space conditions.

Discharging printed products in digital printing

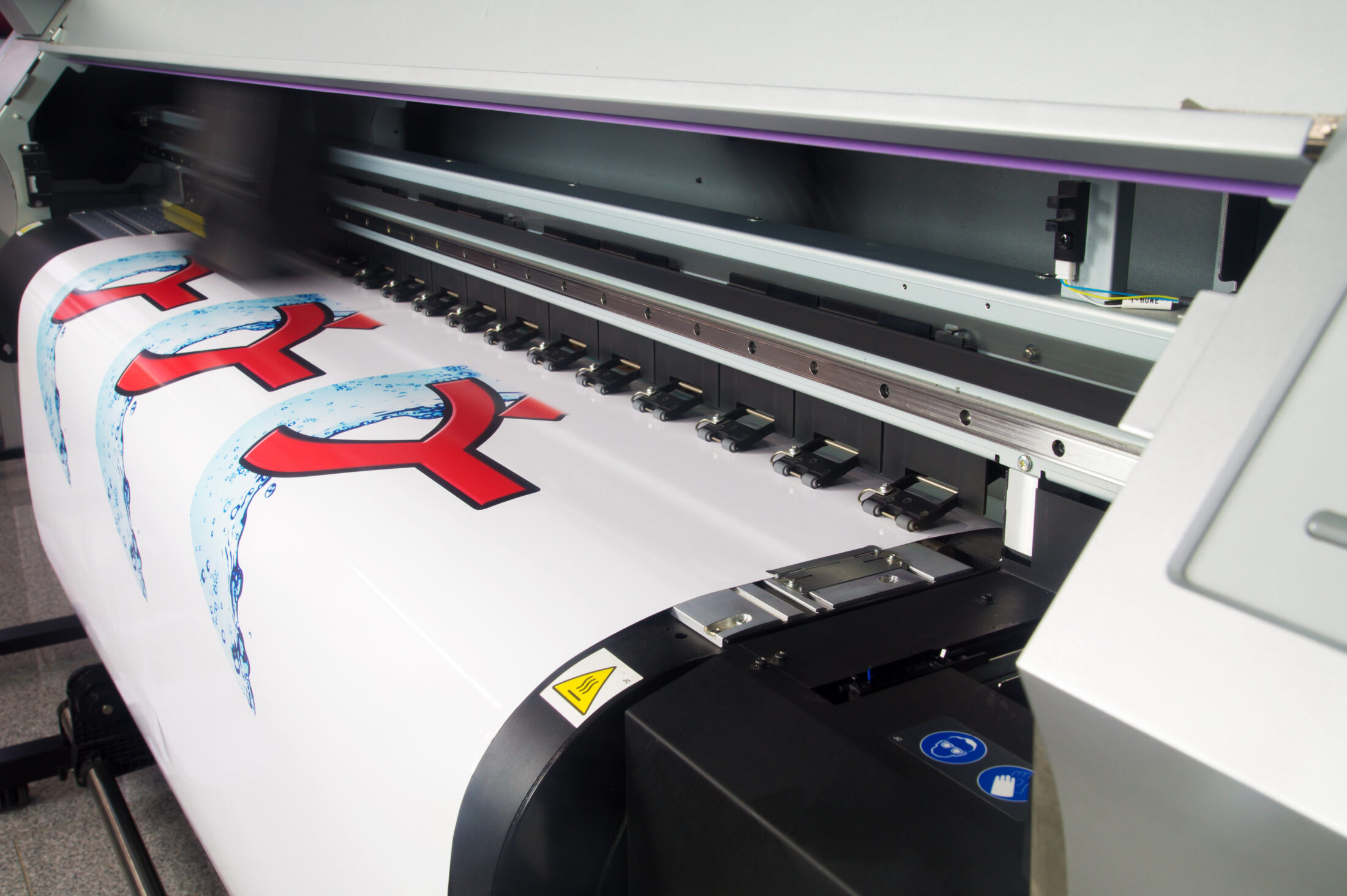

A digital printing press prints paper

On a Xeikon digital press, the paper is processed from the roll, preheated, printed and burned in.

Can the printed products become electrostatically charged?

The sheets are extremely highly charged after the format cut, making them difficult to push open and further process. The discharging bars installed in the press in their original state are not sufficient to discharge the printed sheets sufficiently.

Our solution

Which Eltex components are used?

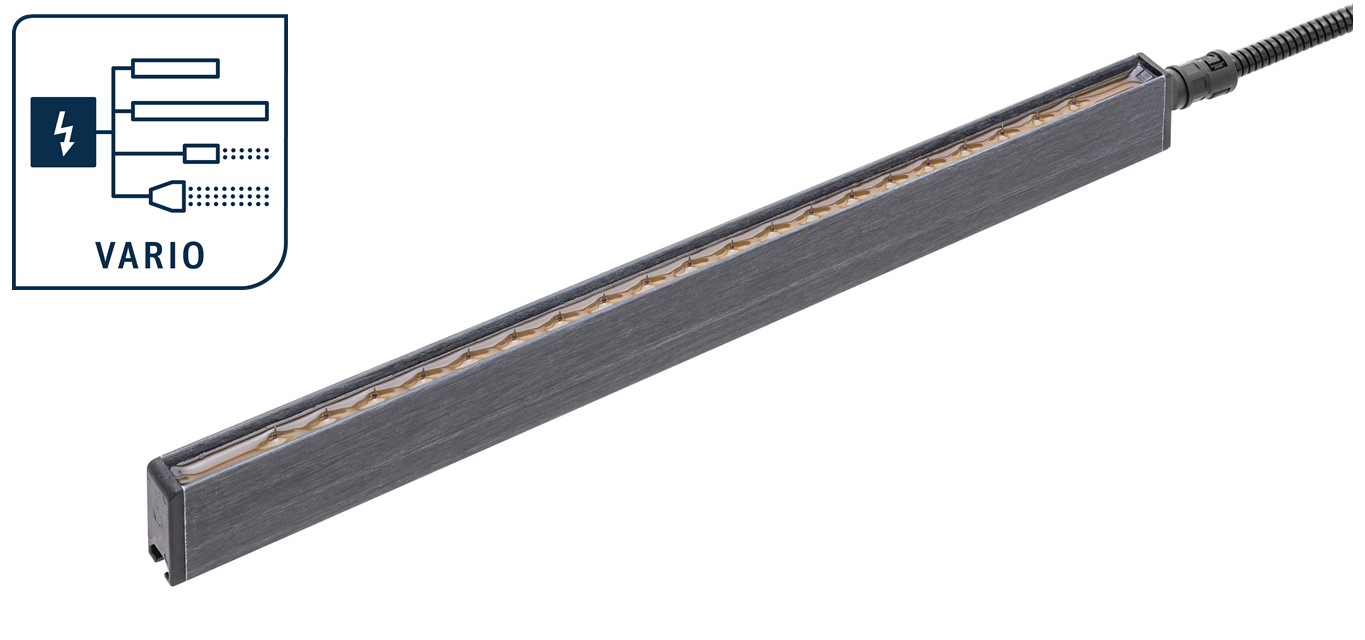

blueBAR R50

The robust all-rounder bar The VARIO discharge bar blueBAR R50 creates a significantly higher active discharge capacity than most discharge techniques. The isolated ground conductor enhances the E-field at the active tips, contributing to increased production and velocity of charge carriers. Thus, significantly more positive ions and free negative electrons are available than with conventional bars. At the same time, the bars have a high passive discharge capacity. The resistance-decoupled tips ensure good discharge performance and make the bar absolutely short-circuit and touch-proof.

PRO IONIZER ES61

The PRO IONIZER is a powerful and flexible device which is suitable for absolutely any application. With the new Performance Control, each discharging component can be supervised and displayed separately. With different adjustable process parameters and several interfaces the PRO IONIZER sets a new benchmark. Click here for more information! Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information on fieldbus integration